Call us: 1800 313 7800

Our Products

भारत की स्टील उत्कृष्टता: गुणवत्ता वाले उत्पादों के लिए आपका विश्वसनीय स्रोत।

Saluja Steel is a premier steel supplier and helps steel users achieve better productivity and profitability. We operate four steel units in Jharkhand, and we have a strong Sales and Marketing channel in eastern India supported through logistics operations. Our products are designed with better stability, ductility, and workability with a quality-assured specification in grades and dimensions. We are well-known for our TMT Bars as one of the best producers in India, and we focus on extreme strength and flexibility. Our products are assured for longevity of use and great application. Saluja Steel produces total quality, with advanced facilities like DRI, SMS Unit, Rolling Mill and Testing Labs.

A diverse array of premium steel solutions

Saluja Gold TMT Rebars

Saluja Gold TMT Rebars are the best choice for construction reinforcement. The Thermo Mechanically Treated (TMT) bar is made from high-strength steel using a special treatment process of water quenching. It forms a tough surface with a strong core that has good ductility (bending & twisting) using a rapid cooling method, which provides good fatigue resistance against repeated cycles of loading. Saluja Gold TMT Rebars are manufactured with multiple grades to meet different requirements for a variety of applications, such as buildings, bridges, dams, etc. Saluja Gold TMT Rebars have outstanding corrosion resistance, weldability, high strength, and is easy to handle. The annual production capacity is 4,00,000 metric tons. Enhance your construction projects with Saluja Gold TMT Rebars.

Producing Saluja Gold TMT bars of the highest quality is our top priority. At every step of the production process, we implement rigorous quality assurance procedures to provide our clients with dependable and long-lasting products. The working method we use to ensure quality is as follows:

- Raw Materials Standard: We buy good-quality raw materials from reliable suppliers who are up to standard with their products

- High-tech manufacturing method: The most modern technology in our factories is used for the production of the materials; they utilise the most advanced technology and equipment. That way, every bar is made with the exact measurements, good strength and the same physical characteristics.

- Hard Testing: We carry out all tests that are necessary for this kind of product, starting with testing raw materials, continuous work, and ending with the finished product. By this, we measure parameters such as tensile strength, elongation, and flexibility.

- Quality Control Methods: The team of skilled quality controllers in our company does the work of regular inspections, and this process assures the high quality of the product. If standard deviations are found, the corrections will be made, and the product quality will be maintained.

- Certified Approvals: We operate our TMT bars with certified standards that not only guarantee perfect quality as per the national standard regime, like BIS, among others. This also testifies to our promise of conformity with local and global quality standards.

- Packing and Delivering: We make sure that the packaging is properly done so that there is no damage while the products are being transported. In this way, the bars can maintain their high quality up until they reach the point of sale in the channel or at the place of customer.

- Customer Happiness: The quality program that we have in place is in alignment with the customer’s happiness program. We love to get feedback from our customers, and we work tirelessly to improve our products based on it.

- Honest and Open Information: We do everything in production in a transparent way. Customers can know about our quality control processes, certifications, and testing methods by simply asking us.

At Saluja Gold, we work very hard and very hard to acquire and maintain the top position in the TMT bars market. We are quite confident in our quality assurance, which in turn results in our products being the perfect choice for secure and long-lasting constructions.

Sponge iron

Sponge iron, commonly referred to as direct reduced iron (DRI), is generated through naturally reducing iron ore by chemically reducing the ore (removing the oxygen). This reduction is accomplished using natural gas or coal as a reducing agent in a non-oxidising atmosphere within a rotary kiln (a large cylindrical vessel lined with refractory material). The resulting material is a metallic material that is highly porous and resembles a sponge, hence the name, sponge iron.

Sponge iron is primarily used as a scrap substitute in steel production using electric arc furnaces (EAF) and basic oxygen furnaces (BOF). Sponge iron also serves as a base material in the production of wrought iron and cast iron. With sponge iron’s potential, we have an annual production capacity of 1,00,000 metric tons.

Billet

A billet is a partially processed metal element that serves an important function in the manufacturing of a variety of other metal products. Billets are usually in a square or rectangular shape and can be made by casting or rolling. They are a significant source of raw material for products such as rods and bars, tubes and pipes, wires and wire products, and can even be used as feedstock for forging (when the billets are heated and then formed, by hammering or pressing). Different sizes of billets meet particular manufacturing applications, and they can vary with the production process. Billets are sold by weight or length and are sometimes stored or transported in stacks or bundles. Our annual production capacity is 4,00,000 tons per metric ton. Learn what billets can do for you.

LRF

LRF stands for “Ladle Refining Furnace,” which is a secondary refining process used in the production of steel. The LRF is a metallurgical vessel used to refine and adjust the chemical composition and temperature of liquid steel, which is usually obtained from a primary steelmaking process such as the Basic Oxygen Furnace (BOF) or Electric Arc Furnace (EAF).

In the LRF process, the liquid steel is transferred from the primary steelmaking vessel to the LRF ladle. The ladle is then transported to the LRF station, where the liquid steel is refined by adding various alloys and fluxes, which help to remove impurities and adjust the chemical composition. The LRF also helps to control the temperature and reduce the gas content of the liquid steel.

The LRF process is important for improving the quality and consistency of the steel, and for ensuring that it meets the specific requirements of the customer or the end-use application. The LRF process is widely used in the steel industry, and is an important step in the production of high-quality steel products.

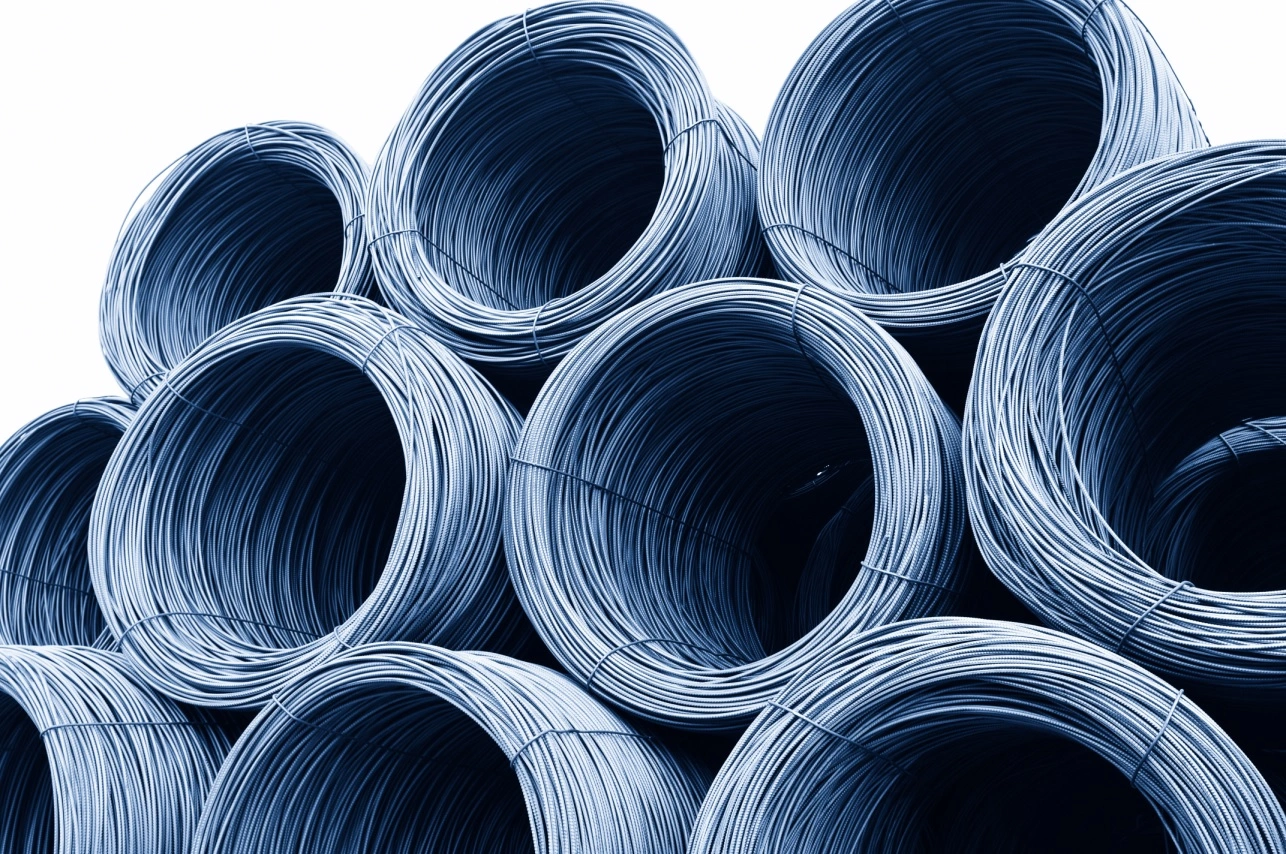

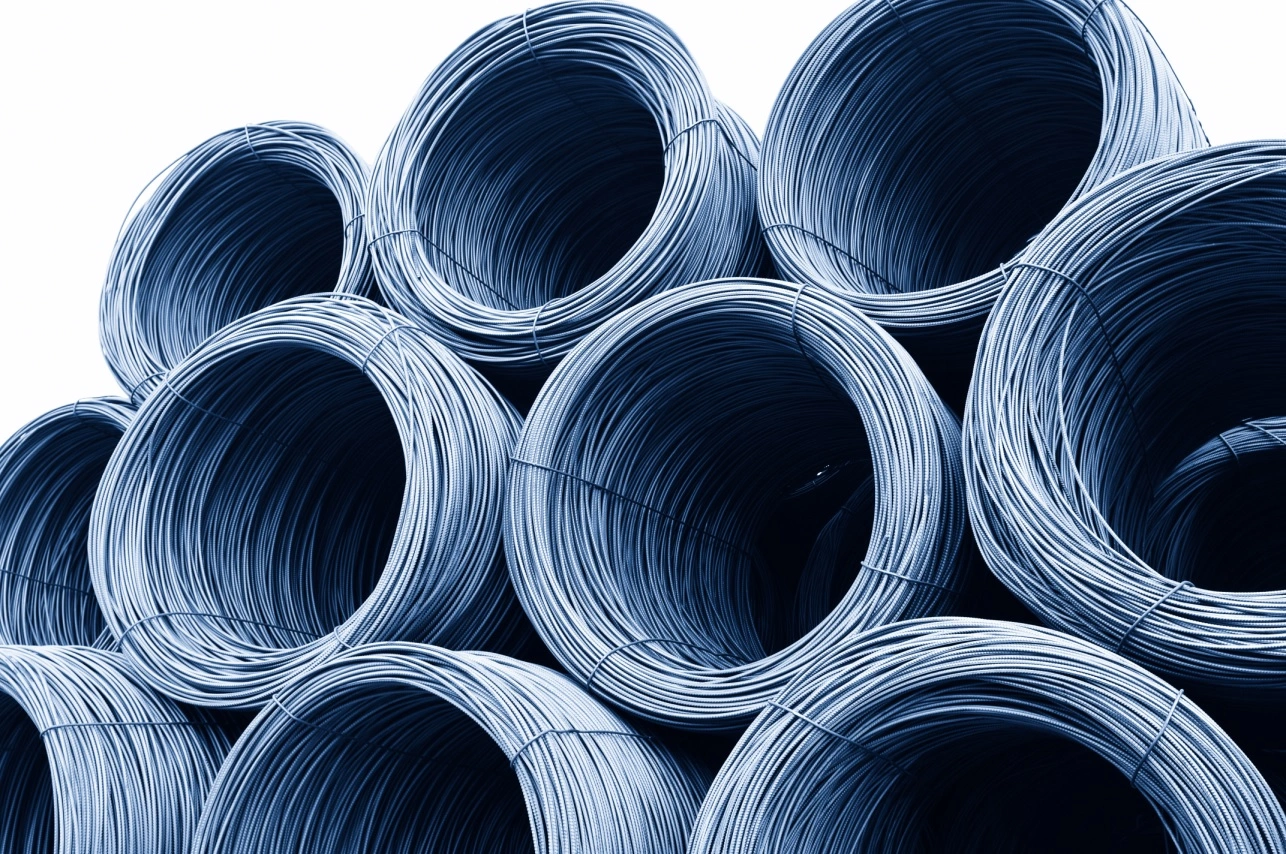

Wire rod

Wire rods, thin metal products with steel as the primary composition, provide a vital raw material for producing a variety of metal products, including wire, mesh, nails, screws, and fasteners. Wire rods are formed through the process of hot rolling, which involves heating several metal bars or billets to high temperatures so the metal can pass through rollers to reduce the diameter, while stretching it to extend its length.

Wire rods are sold in coils, with sizes and grades available for various applications. The wire rods may be drawn, cold rolled or heat-treated to achieve the performance and dimensions required. Wire rods are used in many industries, including construction, automotive, manufacturing, and more. Enhance your metalwork projects with wire rods, an alternative to other products.

Affordability for Every Construction Requirement

Explore our new SALUJA GOLD TMT Bar prices per state, for dealers and buyers of TMT Bars. As one of India’s largest TMT Bars producers, SALUJA STEELS has a large geographical area of coverage, including states such as Jharkhand, Bihar, Uttar Pradesh,West Bengal, North East States, Jammu & Kashmir and Odisha. Our SALUJA GOLD SG600 TMT bars are versatile and available in all sizes, 6mm to 25mm. Our prices remain competitive and will be updated and supervised regularly for each state, while always providing the best prices and best quality. The accredited TMT Bars have gone through ISO Certification, held a BIS License, and are well known for their strength in many significant construction projects only controlled and checked manually to assure accuracy of construction quality.

Your trusted source for Top-Quality, high-grade TMT bars that redefine strength and reliability in the construction industry. Our TMT bars are renowned for their exceptional and unmatched strength, durability, and flexibility, making them the ideal choice for all your construction needs.

Contact Company

-

Enquiry

092 6363 5108

092 6363 5125

Toll Free - 1800 313 7800

- Saluja Steel & Power (P) Ltd. Beside JRG Bank Bhorandia Mahtodih,Tundi Road Giridih - 815302, Jharkhand (India)